Aspire Mining Limited approached Smedley’s Engineers for assistance in dimensioning and communicating the benefits of Higher Productivity Vehicles for a mine haulage operation in north-western Mongolia. We leveraged our experience with PBS to advise Aspire on multi-combination freight vehicles, including roadway and intersection suitability, powertrain and prime mover suitability, and resultant cycle times, payload hauled and fuel consumed.

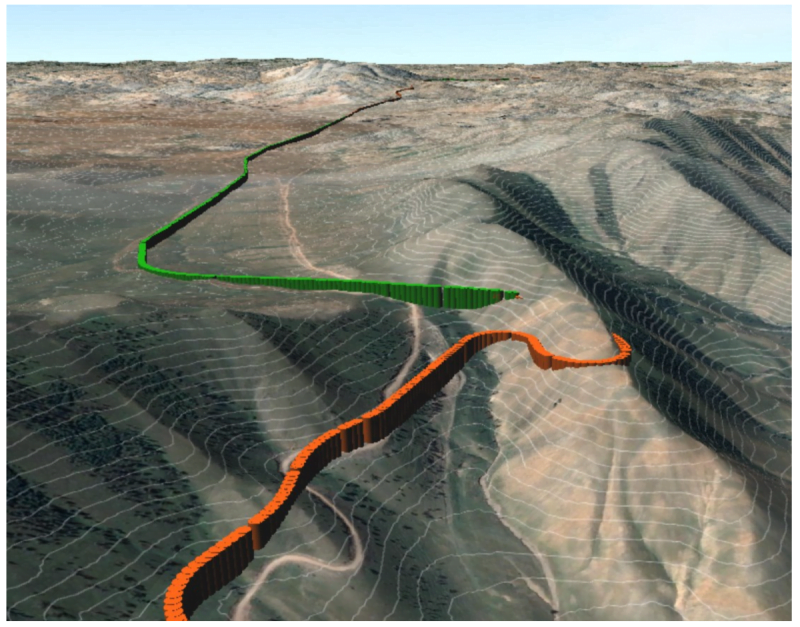

Figure 1: Sample RPM and Acceleration Demand histograms from the cycle analysis

Smedley’s Engineers prepared a range of recommendations for the road network conditions suitable to support Higher Productivity Vehicles, in addition to broad guidance on suitable configurations and the trade-offs inherent in selecting various HPV combinations.

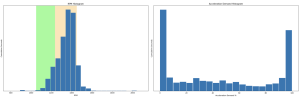

Figure 2: Sample Elevation, Gear, RPM and Velocity traces from the cycle analysis

The problem definition was unique, with Aspire providing over 600 km of conceptual haul road strings with a range of alternative segment options, mass combinations and prime movers for consideration. Communicating the benefits of HPVs in a new environment requires a holistic approach. Aspire requested the vehicle speed and travel time elapsed at each chainage in the strings, plus information on sight distance criteria, fuel consumption and safe cornering and descent speeds for complete roundtrips.

With large geospatial input and output datasets to handle and a substantial test matrix to iterate through, we significantly re-wrote our 1D models for the task, introducing automation and improving stability and simulation turnaround times. To capture the full impact of small changes to simulated driver behaviour at highway cruise speeds, the modelling calculated every parameter five times per second, over a 20 hour round trip.

“It was a great opportunity for Smedley’s Engineers to be involved in the technical evaluation of an HPV concept in a country that doesn’t currently benefit from the reduced vehicle movements that come with safer and more efficient freight systems. The Australian PBS experience of well-managed fleets moving huge freight volumes, at the same time delivering benefits to road managers and other road users, is proof that any country with a similar freight task should consider HPVs. Aspire are an engaged and passionate client with a real interest in global best-practices.”

Dion Simms, Smedley’s Engineers Project Lead

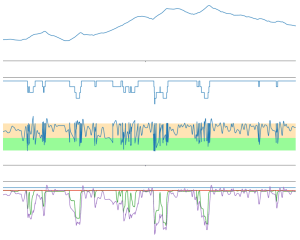

Being a project with diverse stakeholders, the requested deliverables included effective visualisation of the results. Smedley’s Engineers leveraged their civil and spatial engineering experience to deliver results packages in a Geographic Information System project. This allowed the Aspire team to freely visualise the outputs at any location along the route, such as gear selected, percentage throttle or combination speed, all laid over aerial imagery and elevation contours for context.

Based upon the outcomes of this study, Aspire is in the process of liaising with Australian-based trailer manufacturers to adapt Australian best practices to Mongolian conditions with intent to manufacture their trailer fleet under subcontract in Mongolia.

Figure 3: Cycle modelling results shown on a conceptual mountain pass, with green representing acceleration demand and orange representing retarder system demand