Navigating the maze of regulatory requirements is a challenge every special purpose vehicle (SPV) manufacturer faces. In Australia, compliance with the Australian Design Rules (ADRs) is not just a legal obligation but a critical factor in ensuring vehicle safety and performance on public roads. As regulations continue to evolve, the importance of ADR Certification for special purpose vehicles has never been greater.

For manufacturers like Terex, these changes brought significant challenges. Their Franna pick-and-carry cranes – including the MAC-35, AT-22, and AT-40 models – required full certification to meet new ADR requirements and secure concessional RAV approvals. Without a clear path through the shifting compliance framework, production delays and market access restrictions could have created major setbacks.

- Terex ADR testing – Test vehicle

- Terex ADR testing – Test vehicle

This blog discusses how Smedley’s Engineers played a crucial role in guiding Terex through the complex certification process. Acting as a vital link between regulatory bodies and manufacturers, Smedley’s ensured Terex met all compliance requirements while keeping production on track.

How do manufacturers maintain operations when regulations change overnight? Keep reading as we examine the strategic approach that enabled Terex to successfully achieve ADR certification and continue delivering industry-leading SPVs to the Australian market.

Smedley’s Engineers Collaborating on the Terex Project

ADR Regulations and Industry Challenges

The Australian Design Rules (ADRs) are a comprehensive set of national standards governing vehicle design, construction, and safety. They ensure that every vehicle on Australian roads meets stringent performance, environmental, and safety benchmarks. For manufacturers, compliance with ADRs is not just a regulatory requirement; it is a commitment to producing vehicles that are safe, reliable and fit for purpose.

The regulatory landscape for Special Purpose Vehicles (SPVs) has undergone a significant transformation. Before July 2023, SPVs were exempt from ADR compliance, giving manufacturers considerable design flexibility. From July 2023 to July 2024, SPVs were subject to partial compliance requirements, focusing on lighting, tow connections and braking systems.

Now, as of July 2024, SPVs must meet full ADR compliance, aligning their design and performance standards with those of standard heavy vehicles.

This rapid transition has created major challenges for manufacturers. Many must now re-engineer components, update testing protocols and secure additional regulatory approvals. The evolving requirements demand that manufacturers balance innovation with compliance while ensuring production continues smoothly. These challenges highlight the importance of partnering with experts who can navigate the complexities of ADR certification and help manufacturers meet the necessary standards without disruption.

ADR Certification: The TEREX Project

The TEREX project represents a pivotal effort to secure full vehicle certification for Terex’s specialised Franna pick-and-carry cranes, specifically the MAC-35, AT-22 and AT-40 models.

The primary goal was twofold: to achieve comprehensive certification under the stringent Australian Design Rules (ADRs) and to obtain concessional Register of Approved Vehicles (RAV) entry approvals. These approvals are essential for allowing these vehicles to be registered and operated on public roads.

Full certification is critical in the heavy vehicle sector as it guarantees that vehicles meet rigorous safety and performance standards, ensuring they are safe for public use.

For Terex, this certification process was more than just compliance; it was about maintaining uninterrupted production and consistent market supply. In a rapidly evolving regulatory environment, particularly during the transition from partial to full ADR compliance for special purpose vehicles (SPVs), obtaining certification was crucial to avoid potential production stoppages that could impact revenue and market competitiveness.

Terex is a well-regarded name in the heavy vehicle manufacturing industry, known for its innovative, purpose-built vehicles that are engineered to perform under demanding conditions.

Their operational needs require not only robust, high-performing machinery but also strict adherence to evolving regulatory standards.

By partnering with Smedley’s Engineers, Terex leveraged expert guidance to navigate these complex certification challenges. This collaboration ensured that their Franna models remained compliant, allowing Terex to continue delivering high-quality vehicles to the market without interruption.

Key Compliance Challenges and Smedley’s Approach

Navigating the regulatory landscape for special purpose vehicles (SPVs) presented several complex challenges for Terex’s Franna models. The transitional ADR requirements posed a significant hurdle. Historically, SPVs were not required to comply fully with ADRs, but the shift from partial to complete adherence forced manufacturers to update their processes rapidly.

This transitional phase meant that Terex initially needed to meet limited ADR criteria, focusing on lighting, tow connections and braking, before progressing to full compliance with all ADR standards. This abrupt change created uncertainty for both manufacturers and the ROVER application assessors responsible for processing certification requests.

Another major challenge was resolving inherent design conflicts. For example, ADRs mandate a maximum vehicle width of 2.5 metres, which directly conflicts with the design of Franna vehicles. These cranes require a broader profile to ensure optimal stability during operation. This design limitation not only affected vehicle performance but also posed a risk of regulatory non-compliance.

Smedley’s Engineers played a crucial role in bridging the gap between Terex and regulatory authorities. By leveraging their extensive technical expertise and deep understanding of ADR requirements, they provided precise guidance on both design modifications and certification processes.

A key part of their strategy involved securing In-Principle Support (IPS) letters from the National Heavy Vehicle Regulator (NHVR). These letters served as formal justifications for specific areas of non-compliance, such as the

necessary width exceedance, ensuring that the vehicles could still be approved for operation without compromising safety. This proactive and detail-oriented approach allowed Terex to maintain production continuity despite evolving regulatory demands.

Terex ADR testing – Equipment set up

Testing, Certification, and Approval Process

The certification process for Terex’s Franna cranes required a rigorous approach to testing and regulatory approval. Smedley’s Engineers conducted extensive testing to demonstrate compliance with key ADRs, including:

● ADR 3: Seats and Seat Anchorages

● ADR 5: Anchorages for Seatbelts

● ADR 13: Installation of Lighting and Light-signalling Devices

● ADR 18: Instrumentation

● ADR 42: General Safety Requirements

● ADR 43: Vehicle Configuration and Dimensions

● ADR 61: Vehicle Marking

● ADR 65: Maximum Road Speed Limiting for Heavy Goods Vehicles and Heavy Omnibuses

● ADR 80: Emission Control for Heavy Vehicles

● ADR 83: External Noise

● ADR 90: Steering System

● ADR 92: External Projections

● ADR 93: Forward Field of View

● ADR 94: Audible Warning

● ADR 95: Installation of Tyres

● ADR 96: Commercial Vehicle Tyres

Each test involved physical validation, design review or international component approval analysis. Upon completion of testing, Smedley’s Engineers managed the Concessional RAV Entry (CRAV) application process through the ROVER portal. By securing approvals on a monthly basis in line with Terex’s production schedule, Smedley’s ensured that each vehicle met compliance requirements while allowing Terex to continue delivering cranes to the market without disruption.

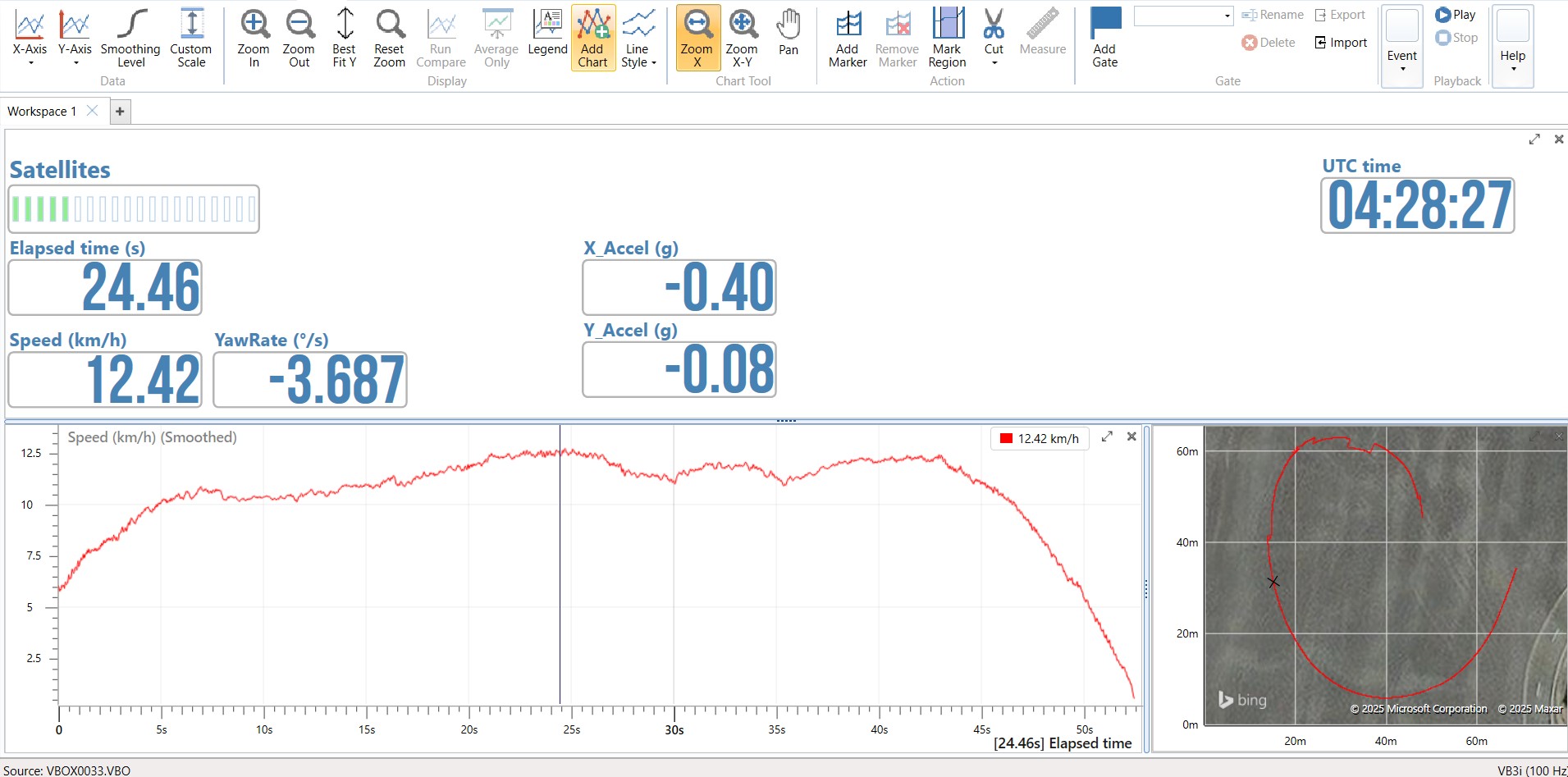

Terex ADR testing – Sample data log

Overall Impact and Benefits

Smedley’s Engineers’ expert management of the ADR certification process enabled Terex to maintain uninterrupted manufacturing of their specialised Franna vehicles. Through proactive engagement with regulatory bodies and by efficiently managing the ROVER portal, Smedley’s was able to streamline the certification process. As a result, each new vehicle received timely concessional RAV approvals. This proactive approach minimised potential production delays during the transitional compliance period and ultimately allowed Terex to continue meeting market demand without disruption.

Furthermore, the benefits of a streamlined certification process extend well beyond operational continuity. For instance, faster approvals reduce administrative overhead and shorten time-to-market, giving manufacturers a competitive edge in an increasingly stringent regulatory environment. In addition, enhanced compliance strengthens both vehicle safety and performance. Consequently, this reinforces market confidence in the product. In Terex’s case, it meant a reliable pathway to register their vehicles and sustain their production schedule, even as ADR requirements continued to evolve.

- Terex ADR testing – Speedometer calibration

- Terex ADR testing – Speedometer calibration

Key Takeaways – ADR Compliance

The TEREX project provides several critical insights into the ADR certification process for special purpose vehicles.

● Early Engagement with Regulatory Bodies: Establishing communication with regulatory authorities from the outset helps streamline approvals and minimise delays.

● Navigating Compliance with Expertise: Partnering with experienced engineers who understand evolving ADR standards ensures a smooth certification process.

● Applicability to Other Manufacturers: The challenges faced by Terex highlight common compliance issues that other SPV manufacturers may encounter. Learning from this case study can help similar businesses proactively prepare for regulatory changes.

● Future Readiness Through Innovation: Staying ahead of evolving compliance requirements requires continuous investment in innovative engineering practices and strategic planning.

- Terex ADR testing -Tyre pressure check

- Terex ADR testing – Weighing-vehicle

Why Work with Smedley’s Engineers on ADR Certification for Special Purpose Vehicles?

Navigating the complexities of ADR certification for special purpose vehicles takes more than regulatory knowledge. It also requires a deep understanding of engineering, compliance processes, and strategic problem-solving.

At Smedley’s Engineers, we bring decades of experience in heavy vehicle certification. We work closely with manufacturers, regulators, and industry stakeholders to streamline approvals and support seamless compliance.

Our team takes a hands-on, solutions-focused approach. We help manufacturers interpret ADR requirements, conduct rigorous testing, and manage the certification process efficiently. In addition, we assist with overcoming design conflicts, securing concessional approvals, and maintaining compliance in a shifting regulatory environment.

That’s why Smedley’s Engineers is a trusted partner for manufacturers who want to keep production moving — without delays or disruption.

Smedley’s Engineers

Get in touch – ADR Compliance

The TEREX project underscores the importance of a proactive and strategic approach to ADR certification. By partnering with Smedley’s Engineers, Terex successfully navigated a complex regulatory landscape, ensuring their Franna cranes met compliance standards without disrupting production.

For other manufacturers facing similar compliance challenges, this case study serves as a blueprint for success. If your company is working through ADR requirements and needs expert guidance, Smedley’s Engineers can help streamline the process and ensure seamless compliance.

Contact Smedley’s Engineers today to discuss how we can support your regulatory and certification needs.