At Smedley’s Engineers, we pride ourselves on being Australia’s leading full-service heavy vehicle engineering firm. With almost 100 years of experience and a dedicated team across Victoria, New South Wales, and Queensland, we offer a complete range of services from vehicle design and compliance to certification and road access permits. Our expertise covers every stage of a heavy vehicle’s life cycle, from concept to operation. We ensure that each project meets the highest standards of safety, performance, and compliance.

The heavy vehicle industry is complex. Given increasing regulatory requirements and operational demands, it’s crucial to partner with a trusted full-service heavy vehicle engineering firm that can handle the entire process. We provide a comprehensive, integrated service that eliminates the need for multiple consultants and simplifies the path from design to roadworthy certification.

A checklist as long as this truck, every box ticked by Smedley’s.

A checklist as long as this truck. Every box ticked by Smedley’s.

We’re proud to highlight one of our standout projects: the Kenworth T909 & A-Double delivered to our valued client, Wickham Freight Lines. This project serves as an excellent example of our full-service heavy vehicle engineering offering. We managed everything from design and modelling to certification and access permits

Smedley’s Full-Service Offering

Smedley’s Engineers stands out as a leader in the Australian heavy vehicle industry. We offer a complete suite of services that cover every stage of a vehicle’s life cycle. As the only full-service engineering firm in the country specialising in heavy vehicles, we provide a seamless, integrated service that addresses every need. From initial design and compliance assessments to vehicle certification and ongoing road access support.

Our team’s expertise spans a wide range of engineering services, ensuring that each project we handle is optimised for both performance and regulatory compliance. Whether it’s creating detailed design models, ensuring vehicles meet Australian Design Rules (ADR) or Performance Based Standards (PBS), or securing the necessary access permits for operations, we are there every step of the way.

Here are some of the key services we offer:

Vehicle Design & Modelling

We provide a full range of vehicle design services, using advanced modelling techniques to ensure each vehicle meets its intended performance and safety standards. Specifically, our team of experienced engineers employs finite element analysis (FEA) and detailed CAD modelling to design vehicles that are not only functional but also cost-effective and efficient.

Compliance & Certification

Navigating the complex regulatory landscape is a critical part of any heavy vehicle project. In particular, we manage all aspects of compliance and certification, including ADR certification, PBS assessments, and vehicle approvals. We ensure that every vehicle we work on meets the highest safety standards, guaranteeing its performance on Australian roads.

Access & Route Assessments

Understanding and securing the right access permits is vital to the operation of heavy vehicles. We offer expert route reviews and access permit applications, helping our clients navigate the often complex requirements for operating on specific road networks. We manage the permit process, ensuring that all the necessary conditions are met for smooth and safe operation.

Manufacturing Drawings & Testing

Once the design and compliance stages are complete, our engineers produce precise manufacturing drawings to guide the construction of each vehicle. Furthermore, we carry out a wide range of testing, including ADR, Road Friendly Suspension (RFS), and Static Roll Threshold (SRT) testing to validate vehicle performance and safety.

Case Study: Kenworth T909 & A-Double for Wickham Freight Lines

One of the standout examples of our full-service heavy vehicle engineering capabilities is the successful delivery of the Kenworth T909 & A-Double for Wickham Freight Lines. This project showcases the depth and breadth of the services we offer, as we managed every aspect from design and modelling to compliance, certification, and securing the necessary road access permits.

The Kenworth T909 & A-Double, designed to transport heavy loads across Australia’s demanding road networks, required meticulous attention to detail. The project was particularly complex, as it involved a combination of custom vehicle modifications and a comprehensive route assessment to ensure the vehicle could operate safely and efficiently.

Our involvement in this project spanned multiple departments within our organisation, each contributing expertise and experience to ensure the project met all regulatory requirements and operational demands. This section will break down the scope of work in more detail, outlining how each department contributed to the successful delivery of the vehicle.

Kenworth K909, Wickhams Freight Lines

Our Scope

Smedley’s Engineers’ involvement in the Kenworth T909 & A-Double project for Wickham Freight Lines was comprehensive, addressing every aspect of heavy vehicle engineering from design and compliance through to certification and access. Each department within our organisation played a critical role, ensuring the project met all necessary safety standards and regulatory requirements.

Vehicle Design & Modelling

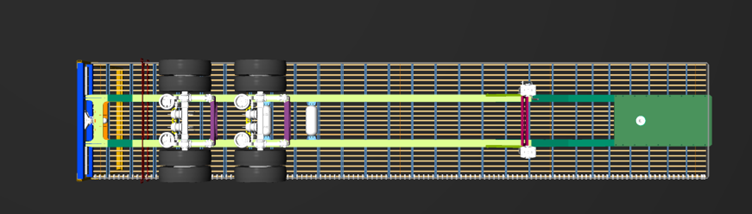

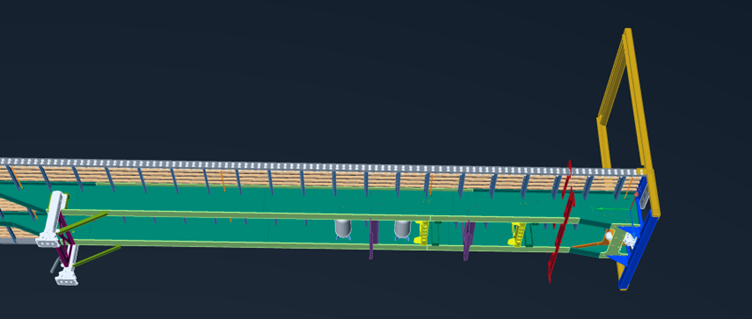

The design phase is critical to ensuring the vehicle performs optimally and meets all required safety standards. For the Kenworth T909 & A-Double, Smedley’s Engineers used advanced finite element analysis (FEA) to simulate and analyse the vehicle’s performance under real-world conditions. This allowed our team to refine the design, improving load distribution and structural integrity. The detailed CAD modelling ensured precision in the vehicle’s construction, while also factoring in aspects such as aerodynamics and fuel efficiency.

Bottom up view

A unique challenge in the design process was the assumption made regarding the unladen trailer CoG height and tare mass. As the trailer had not yet been built and was being custom-designed by the manufacturer, SONADOR, we had to rely on preliminary data. However, our expertise in heavy vehicle design allowed us to make accurate assumptions, ensuring that the design would meet the necessary requirements once the trailer was completed.

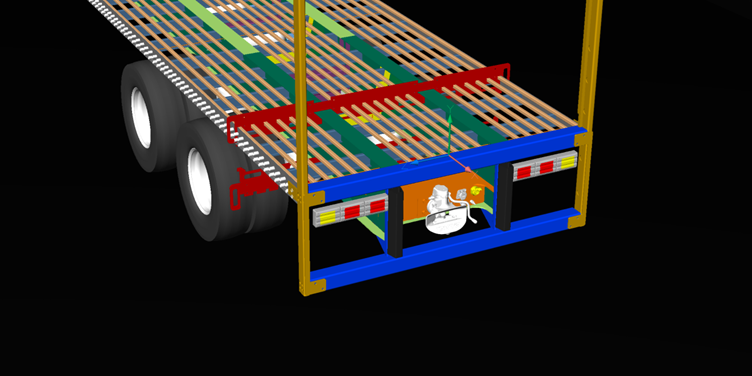

The collaboration with the trailer manufacturer was essential in finalising the design, with ongoing communication between our team and SONADOR to refine key elements like the trailer’s tow coupling mount, skid plate design, and underrun protection. This ensured the final product met all industry standards, including ADR 62 (for rear underrun protection).

Manufacturing Drawings & Testing

Once the vehicle design was finalised, the next step was creating detailed manufacturing drawings that would guide the production process. These drawings ensured that all components were fabricated to the highest standards of quality and precision. Our team’s expertise in creating clear and accurate manufacturing drawings was vital in ensuring that the final product was built exactly to specification.

Testing is an essential part of the engineering process, validating the design and ensuring compliance with safety standards. For the Kenworth T909 & A-Double, Smedley’s Engineers conducted a series of rigorous tests to ensure the vehicle’s performance. ADR testing, Road Friendly Suspension (RFS) testing, and Static Roll Threshold (SRT) testing were carried out, evaluating the vehicle’s compliance with safety and operational performance requirements.

The vehicle successfully passed these tests, demonstrating its ability to meet all regulatory standards, including the stringent requirements for roadworthiness and safety.

Rear underrun and tow coupling mounting

ADR Compliance & PBS Assessments

Achieving ADR compliance and PBS (Performance Based Standards) certification is a crucial aspect of heavy vehicle engineering. For the Kenworth T909 & A-Double, Smedley’s Engineers took a thorough approach to ensure the vehicle met all necessary safety standards and performance requirements. The vehicle needed to meet 16 safety standards and 4 infrastructure standards, all critical for ensuring the vehicle’s safe operation on Australian roads.

One of the primary challenges in this project was ensuring the vehicle met the PBS Level 2 and Level 3 access requirements. The vehicle’s overall length of 31.686 metres exceeded the 30-metre limit for Level 2 access, which required an individual route assessment for road access. As a result, the vehicle’s access was limited to specific routes that were approved on a case-by-case basis, subject to Road Manager Consent.

Our team worked closely with Wickham Freight Lines and the relevant authorities to secure the necessary approvals, ensuring the vehicle would be able to operate safely within the constraints of the network. This level of detail is just one example of how Smedley’s Engineers goes above and beyond to ensure the vehicle is compliant with all regulations while optimising its operational efficiency.

Vehicle Certification & VIN Submissions

Once the vehicle was designed, tested, and assessed, the next crucial step was vehicle certification. This process involved submitting the vehicle details to the National Heavy Vehicle Regulator (NHVR) and the National Exchange of Vehicle and Driver Information System (NEVDIS) for VIN submission and approval. The certification ensured that the Kenworth T909 & A-Double complied with Australian road standards and was legally roadworthy.

As part of the process, the VIN submission was handled to ensure the vehicle’s registration and compliance were recognised across all states and territories in Australia. This submission was essential for allowing Wickham Freight Lines to operate the vehicle within the national fleet.

Our team ensured that all certification steps were completed efficiently, allowing the vehicle to be registered and ready for operation.

Access Permits & Route Review

Once the vehicle received certification, securing the right access permits and conducting route reviews was the final step to ensure the vehicle could operate smoothly across Australia’s road network. Given the size of the Kenworth T909 & A-Double, access to certain routes was restricted, and individual route assessments were required.

Smedley’s Engineers handled the entire access permit process, ensuring that Wickham Freight Lines had the necessary approvals to operate the vehicle on roads that allowed for its unique size and configuration. The Level 2 and Level 3 access restrictions meant that specific routes had to be reviewed and approved on a case-by-case basis. This complex process ensured the vehicle could be used safely and legally on approved routes across Australia.

Key Innovations in the Kenworth T909 & A-Double Project

Throughout the Kenworth T909 & A-Double project for Wickham Freight Lines, Smedley’s Engineers introduced several key innovations that enhanced the design, manufacturing process, and overall performance of the vehicle. These innovations were critical in ensuring that the vehicle met both operational and regulatory requirements while also improving manufacturing efficiency and reducing costs.

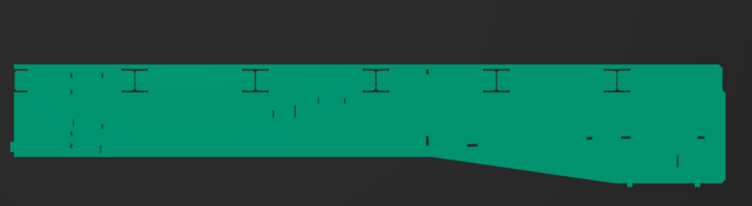

Tab and Slot Manufacturing Design

One of the standout innovations was the use of a tab and slot arrangement for the trailer construction. This design approach allowed for laser-cut flat plate sheet to be easily assembled without the need for large, expensive assembly drawings. The tab and slot design provided several advantages, including:

- Cost savings: By eliminating the need for complex assembly drawings and reducing the number of jigs and fixtures required, this design saved both time and money during the manufacturing process.

- Increased flexibility: The tab and slot approach allowed for greater flexibility in meeting customer orders, as parts could be fabricated and assembled quickly with fewer constraints.

- Error reduction: The unique tab and slot patterns acted as poke-yoke features, ensuring that manufacturing errors were minimised. Each pattern was specifically designed to avoid incorrect assembly, improving the overall quality control of the vehicle.

These innovations contributed significantly to the efficiency of the vehicle’s production, ensuring that the Kenworth T909 & A-Double met the required standards while being delivered on time and within budget.

Poke-yoke

Lightweighting Process

Another significant innovation was the lightweighting process undertaken during the trailer design. The initial trailer design was heavier than required, which impacted the overall payload capacity. Smedley’s Engineers worked closely with the trailer manufacturer, SONADOR, to remove unnecessary weight from the design without compromising structural integrity.

The lightweighting process improved the carrying capacity of the trailer, making it more efficient and cost-effective for Wickham Freight Lines. This also helped to reduce fuel consumption, which is a critical consideration for long-haul operations.

Tailored Design for Operational Needs

The design of the Kenworth T909 & A-Double was not only innovative but also tailored to the specific operational needs of Wickham Freight Lines. For example, the tow coupling mount and skid plate design were specially tested to meet the requirements of ADR 62, a critical standard for rear underrun protection. This level of detail ensured that the vehicle was optimised for both safety and operational efficiency.

The vehicle’s design, including the suspension hangers and the integration of the kingpin skid plate, was also optimised for performance in demanding conditions, ensuring that it would withstand the rigours of long-distance transport across Australia’s varied landscapes.

The Kenworth T909 & A-Double project for Wickham Freight Lines demonstrates the exceptional capabilities of Smedley’s Engineers in providing full-service engineering solutions for the heavy vehicle industry.

From the initial vehicle design and modelling to compliance, certification, and access permits, our team handled every aspect of the project with precision and expertise. The successful outcome of this project is a testament to our nearly 100 years of experience in the field and our commitment to delivering high-quality, innovative solutions for our clients.

The Heavy Vehicle Specialists

At Smedley’s Engineers, we understand the complexities of heavy vehicle engineering and strive to provide seamless, integrated services that ensure your vehicles are compliant, efficient, and ready for the road. Whether you need assistance with vehicle design, PBS certification, access permits, or roadworthy certification, we are here to support every step of the process.

If you’re looking for a trusted partner to handle your heavy vehicle engineering needs, Smedley’s Engineers has the experience and expertise to ensure your success.

Contact us today to discuss how we can assist with your next project. We’re here to help you navigate the complexities of the heavy vehicle industry and deliver optimal solutions tailored to your requirements.